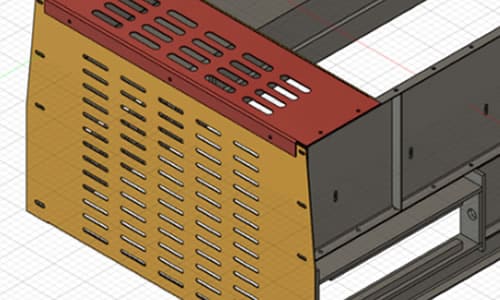

Ingalls Conveyors Fab Metal Shop is a full service shop equipped with Press Break , Welding (Tig, Mig), Band Saws, Sheers, and CNC Punches.

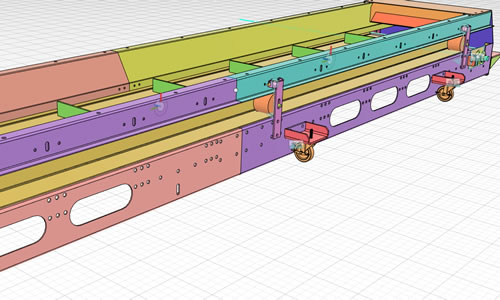

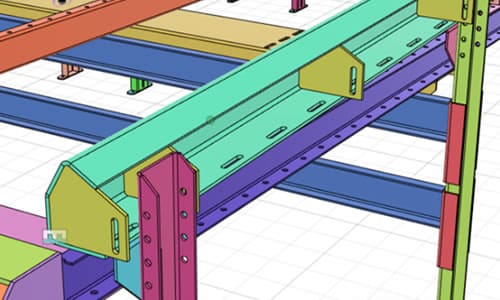

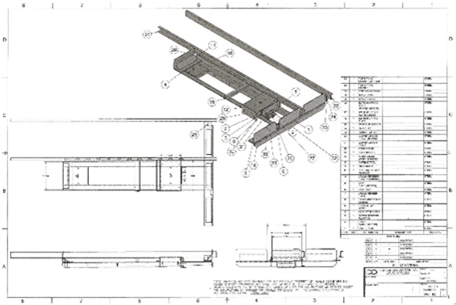

We have in house Auto CAD design and detailing of common Material Handling accessories such as:

Ingalls Conveyors Fab Metal Shop is a full service shop equipped with Press Break , Welding (Tig, Mig), Band Saws, Sheers, and CNC Punches.

We have in house Auto CAD design and detailing of common Material Handling accessories such as:

Please call 1-800-826-4554 or email info@ingallsconveyors.com to contact one of our engineering staff members about your specific metal fabrication & welding shop requirements.

Grab the slider control in the middle of each example below to compare the design to the result.

Bring your design and we’ll do the rest. We can make your CAD drawing into the part you envisioned. If you don’t have a CAD file, don’t worry. Our in-house engineering team can collaborate with you to get the part you need – Working together to get the perfect fit.

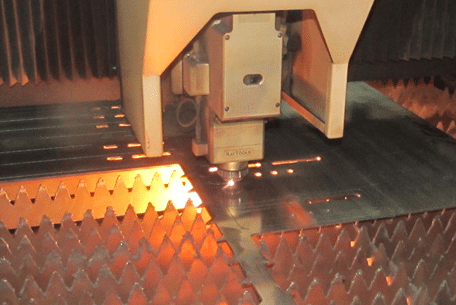

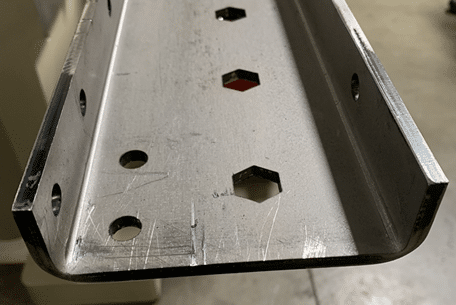

We have the capacity to cut up to 0.625” material thickness. Our shop is equipped with saws, torches, shear and state-of-the-art Fiber Optic Lasers. All parts are deburred to create the proper edge preparation and safeguard you from unwanted burrs prior to shipping.

Our Press Brakes have the capability of bending material up to ¼” thick and total bend lengths up to 120”. We have the proper tooling, talent, and expertise to create your specific part.

Our welders have more than 35 years of experience and are trained in a variety of welding techniques such as Mig, Arc and TIG. Our welding experience will get your parts completed efficiently and effectively.

Our assembly department can put the finishing touches on your design and get it ready to ship. We have the capacity to assemble multiple components with either hardware or welding construction.